Non thermal laceration is one of the best ways to slice hard substances. This technique gives precise cutting results without eliminating physical properties of the substance. Traditional substance slicing of laser or flame involved generation of heat. They gave adequate cutting results but took physical properties of the substance. However, non thermal or abrasive water jet laceration does not carry such problems. Just keep your focus and follow these tips for best results.

- Slicing a thick substance- Slicing thick materials through this technique can create some problems. Basic cutting heads will not give effective results on 0.100 inch thick substances. You have to use a better parameter combination to increase cutting efficiency. Instead of 5 or 6 HP, you have to use a parameter of 25 HP to avail best cutting results.

- Cutting through air gaps- another thing which should be considered while cutting is avoiding air gaps. While using the machine, you should give best of your efforts to avoid slicing through air gaps of 0.020 inches. These air gaps opens up the jet and gives rough cutting of lower layer. It ruins the complete cutting experience within no time. Therefore make sure, you avoid air gaps while using the machine.

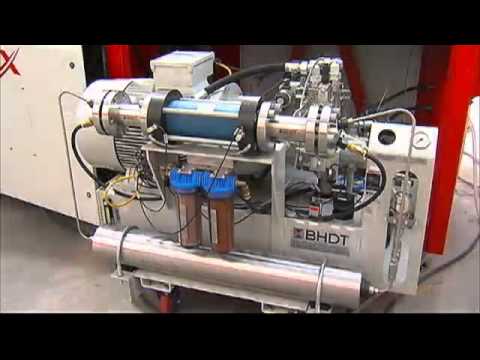

- Check your machine – For proper cutting of different materials, don’t forget to check flexibility, control and efficiency of water pressure. Without flexibility to decrease or increase pressure, you cannot slice through different substances. Along with this, you should also check efficiency of vacuum assist and other features for accurate cutting of different machines.

- Maintenance is important- For optimum performance while cutting, maintain the machine perfectly. Lack of care and maintenance is the biggest reason due to which machines lose their efficiency. Their cutting strength decreases and rough results are achieved while slicing thick substances. So, maintain your machine efficiently before slicing any substance with it.

- Various mesh sizes- If you are looking to use different mesh sizes, try to add a small or large bulk transfer. Without bulk transfer hopper, you cannot achieve efficient results while slicing different substances. Proper knowledge about different mesh sizes plays a big role in achieving adequate perfect cutting results.

- Read the guide or take professional support- The last thing which should be considered while using waterjet machine is seeking additional support. Before starting your cutting job, read all the instructions and warnings to achieve best results. You may also seek additional advice from professional cutting experts before initiating the task. Added support and guidance can play a big role in achieving best cutting results within no time. After understanding the working and cutting techniques, you can slice off any substance in an easy and efficient manner.

These were some tips which can help in slicing hard substances. Water jet laceration is one of the best and most reliable ways to cut off different materials. The machines offer many benefits and give precise and accurate cutting results. To know more about non thermal or water jet laceration, visit at http://semyx.com/.