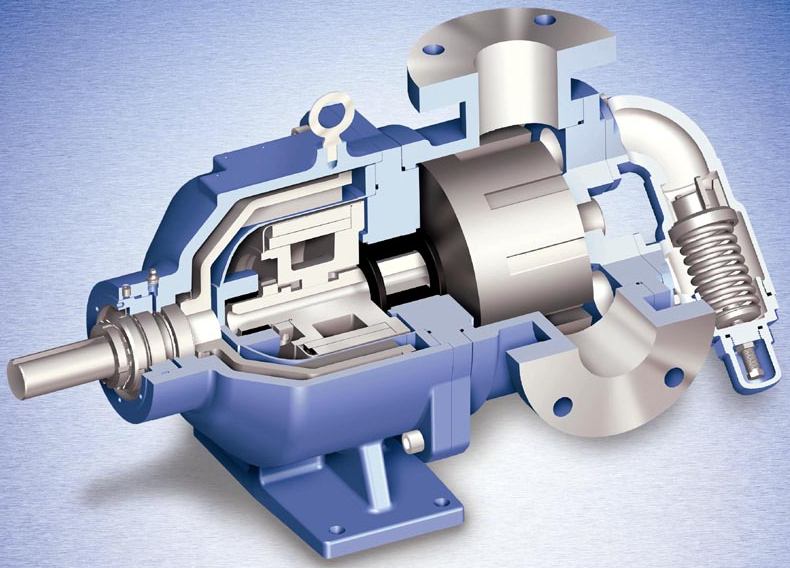

Centrifugal pumps are the perfect choice for pumping liquid chemicals without any problems. These pumps are subclasses of Turbomachinery which are dynamic and axisymmetric. These pumps are capable of transporting fluids with the conversion of rotational kinetic energy into hydrodynamic energy. The rotational energy is provided by the engine or the electric motor. When the fluid enters the impeller, it is accelerated by it and flows rapidly towards the diffuser and from there it exits the pump. These pumps find their use in pumping of petroleum, sewage, petrochemical and water. The reverse mechanism of the centrifugal pumping is the main principle of the water turbine that converts the potential energy of the water pressure into rotational mechanical energy.

These centrifugal pumps come with a wide choice of wetted materials such as stainless steel, PTEE, polypropylene, PVDF and Hastelloy C. The maximum pumping capacity of these pumps can be up to 4000 m3/hr. The differential heads up can be up to 220 metres with a single stage and 700 metres with multi stage pumps. These pumps come with a wide range of options such as mechanical seals, API 685 pumps, API 610 pumps and leak free magnetic drives. These pumps are specially designed for heavy duty applications such as in petrochemical industries and refinery applications. These pumps are of various types and standards.

- Plastic Centrifugal DB Series

The DB series comes with a leak free magnetic drives that are specially designed for corrosive fluid handling and hydraulic efficiency. These pumps are made of PVDF or polypropylene. The major advantage of these pumps is low power consumption and low maintenance cost with long life cycle. These pumps are designed to be a dry run without any damage and even in the most corrosive environment.

- ETFE Lined Centrifugal UC Series

These pumps are ideal for pumping dangerous chemicals. These are leak free magnetic driven pumps which are combined in a hard iron outfit with a Tefzel lining for utmost corrosion resistance. Its ultra-Chem range is capable providing utmost reliability in most extreme chemical processing.

- Thermoplastic Mechanical Seal Centrifugal Pumps

These pumps are perfectly suited to handle the chemicals where metallic pumps can suffer corrosion. These pumps are made of solid blocks and their manufacture does not involve injection moulding or welding. These are the most susceptible to stress cracking. These pumps are available in various configurations, you can choose the one which is perfect for your requirement.