Expansion joint systems are turning out to be the new alternatives for pipelines and pipes. Whether it is a sugar; cement; petrochemical; power generation; metal refining; aerospace; rubber; shipping or any other manufacturing sector, the application of the piping expansion joints can be observed everywhere. An experienced and reliable metal bellows manufacturer does everything starting from identification of bellows material to final inspection involving prototype testing for fatigue life,spring rates,pressure retaining capacity,burst pressure test, hydro-pneumatic pressure test, X-ray of weld joints etc.

Piping expansion joints are the new buzzword of manufacturing units. This innovative invention is effectively assisting to make structural changes like those produced by tightening pipes and metallic tubes or thermal expansion. If you are going to set up a new factory unit, along with steel, cements and bricks, you must purchase quality metal bellows expansion joints to safeguard your pipelines from thermal movements and mechanical movements like earthquakes and lad settlement. These parts play a great role in proper functioning of the machineries and hence make the manufacturing process swift.

But, there are a few basic things you must keep in mind before you expend on metallic piping joints.

What are the Benefits of Metallic Expansion Joints?

You can consider these compensators as the base of any piping structure. The modern technology has overcome traditional techniques, and luckily the benefits are also multiplying.

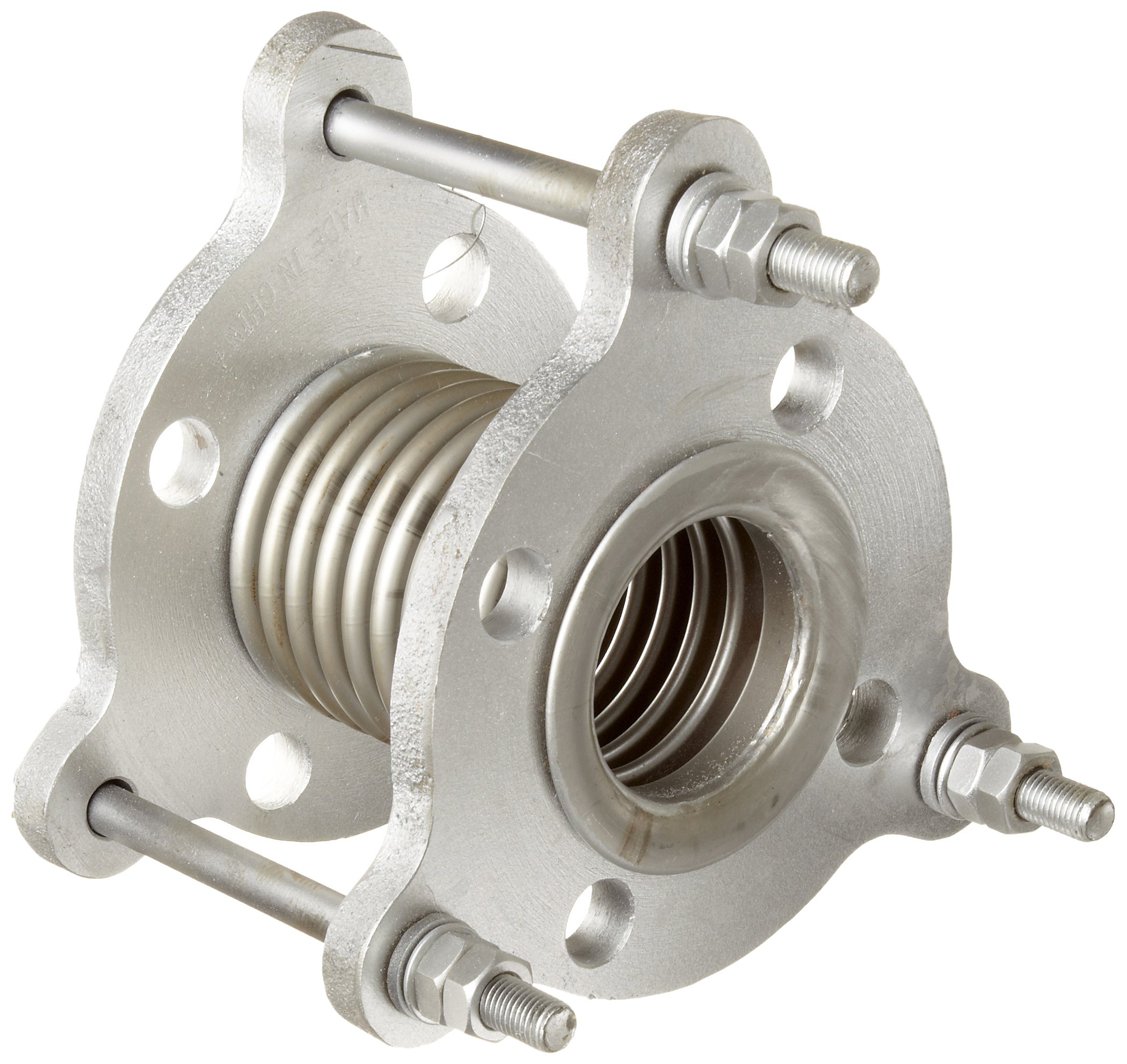

The most important usage is that it allows movement in the pipelines. The metallic bellows is an elastic segment of the expansion joint which usually comprise of many flexible folds. This makes a piping system more flexible and you can bend the pipelines to desired directions. This also protects the pipes from frequent pulsations, vibrations and thermal growth; otherwise the pipes may show signs of wear and tear as well as leakage. In latest metallic expansion joints, the metallic bellows are produced with ‘multi-ply’ designs.The advantages of these metallic bellows are listed below:

Resistance to Very High Pressure

- Small dimension and little force-rates adjustment

- Greater movement absorption

- Standard check whole technology for early leakage detection

- Complete rupture-proof

- Filling against structure-borne clatter till 20 dB

- High quality, corrosion-proof materials like Incoloy, Monel, Inconel, titanium and Hastelloy

- What to Look for While Purchasing?

Purchasing metal bellows expansion joints is not a cake walk until and unless you are aware of the nitty-gritty of it. In addition, measurement, installation and proper functioning are few other important aspects that should also be kept under consideration. So, wouldn’t it be a better idea to purchase from a company that excels in the field? Definitely ‘yes’. Likewise there are many other things you should look for while purchasing. Some of them include:

Wide Range of Expansion Joints Availability

Look for a company where you can find several types of metal joints, starting from axial, universal, hinged , gimbal, pressure balanced,externally pressurized , jacketed ,heavy wall, rectangular to various other multi-ply compensators.

Vast Number of Services

To make your task easy and quick, bank on a manufacturer which also offers services like inspection, storage, installation, testing, audits and time to time inspections.

ISO Certified and Experienced

Look for an ISO certified company with profound know-how in this area, so that you can get the best out of your penny. Also check if the company meets International Environment standard or not.

It often becomes confusing to choose the right piping extension joints among various types, sizes and designs. But, if you can find a trusted supplier, your task is half done. So, find out a supplier and easy up the process to get the best benefits of installing metal bellows expansion joints from the manufacturer directly rather than an intermediatery like a trader or a stockist.