Pallets are an extremely beneficial commodity and are ideal for transporting a wide range of goods, including consumer products, food and pharmaceuticals. It helps to keep the products safe and secure, as well as making the process of moving items from one place to another simple and efficient. With pallets becoming an everyday product, we don’t always analyse the true benefits that they bring to businesses.

Pallets are often taken for granted today, with many businesses using them as a matter of course every single day. By 2017, it is expected that there will be 1.3 billion pallets in use across the global; with an estimated growth of 3.5% each year. When pallets were first introduced to the market, however, they revolutionised the process of material handling, making it far more efficient in terms of both time and cost. It is now possible to complete jobs that would have taken days in a matter of hours.

Quicker Processing

One of the key benefits of pallets is that they enable products to be moved faster and more efficiently than if it was necessary to move individual containers. This allows delivery trucks to be turned around faster, making the whole logistical system more efficient. If trucks are spending less time unloading or loading at the warehouse doors, companies can accommodate more trucks on a daily basis. A faster system of processing also means that refrigerated products are placed in appropriate storage facilities sooner, so there is less risk of the goods becoming spoilt.

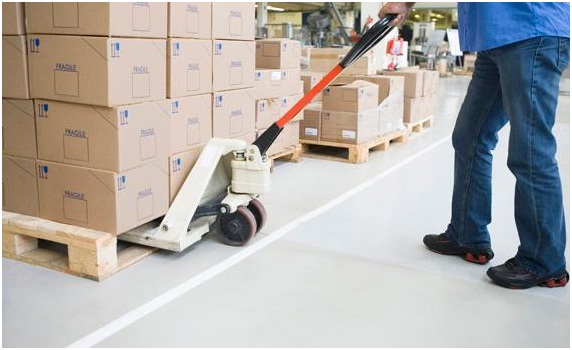

Reduction in Manual Handling

Goods that are loaded onto pallets can be moved by fork lift trucks and other material handling equipment. This reduces the requirement for manual handling, which can benefit both the business and the employees. Less manual handling will reduce the degree of product damage that is caused if goods are dropped or handled incorrectly. Companies can also put in place additional measures to protect the items. For example, they could buy pallet wrap machines to secure the goods.

With less of a need for manual handling there is a reduced risk to employees of sustaining injuries. Manual handling injuries are responsible for a large number of days off work, which can impact on the efficiency of a business. In 2013/14, companies lost around 909,000 working days because of handling injuries, with each incident being responsible for an average of 6.6 days.

Efficient Transport and Storage

The use of palletised goods makes the whole logistical process more efficient, from the transportation of goods through to the storage of them. The pallets have been designed to be used with material handling equipment and other pallet related machinery, such as the items available from suppliers like packaging-machines.co.uk.

Benefits to the Customer

Customers usually prefer to receive goods on pallets, so by doing so you are providing an enhanced level of service. This makes it easier for them to allocate storage space and reduces the time taken to process orders. Therefore, the use of pallets offers advantages to all stages in the logistical cycle: from the original manufacturer through to the end retailer.